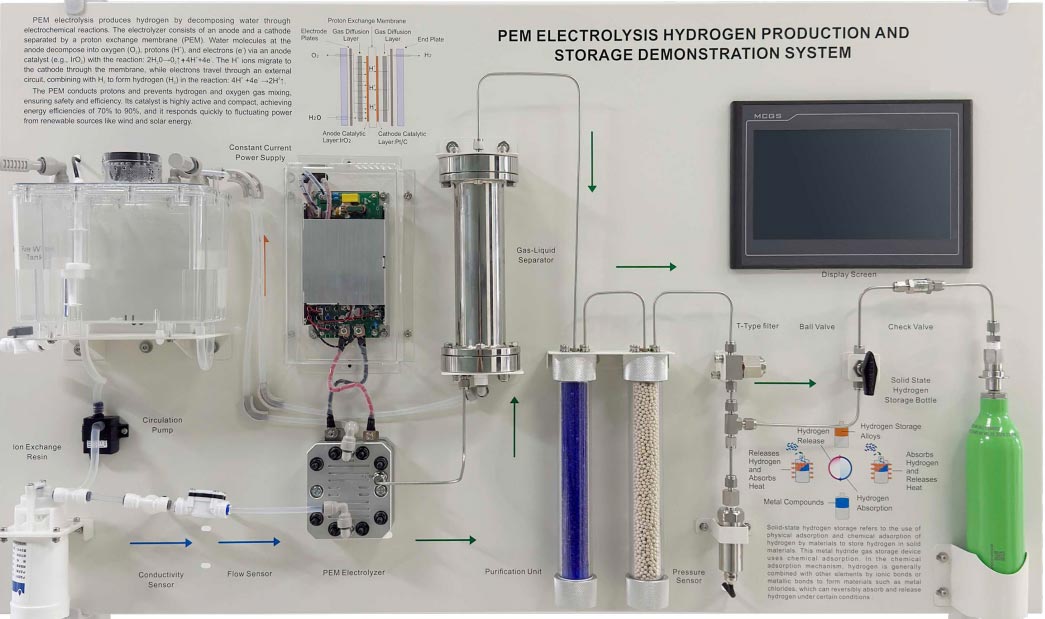

PEM Electrolyzer 200

A real industrial state-of-the-art Hydrogen production line, the smallest in the world, compacted on a school-training-board, controlled by SIEMENS smart industrial grade PLC, for didactic purposes.

Innovation and Future-Oriented Technology.

Wandaa is ready to lead the way into Industry 4.0. Our educational products, the PEM Electrolyzer 200 and PEM Fuel Cell 200, are fully compatible with the Internet of Things (IoT). As a trusted partner, Wandaa will showcase our Hydrogen Training Boards at the Innovation Week (January 27–29, 2026) hosted by Zukunftswerkstatt 4.0 Esslingen.

The Wandaa GmbH has been committed to sustainability and renewable energy since its founding over 25 years ago.

The company initially focused on processing and reusing industrial plastic waste recycling and renewable energy purposes.

During the pandemic, Wandaa Solar was established, offering both the sale and installation of photovoltaic systems.

Through careful market observation, the growing demand for e-bikes was identified, leading to their addition to the product portfolio. However, after a short but intensive engagement with this topic, the poor recyclability—and especially the significant environmental impact of battery production—became apparent. As a result, the company transitioned to hydrogen-powered bicycles.

Our engagement with the new technology of hydrogen deeply fascinated us, prompting us to explore the subject more thoroughly. Today, we offer a range of innovative hydrogen-based products.

With the energy transition, the phasing out of internal combustion engines (ICE), and the rise of Industry 4.0, hydrogen is becoming an increasingly frequent topic of discussion among industry experts. It is clear: the industrial sector is undergoing a revolution.

We are ready for change!

The Wandaa Group team specializes in renewable energy—particularly hydrogen systems for laboratory and educational purposes.

We develop and present state-of-the-art, intelligent hydrogen products, such as the world’s newest models of the Electrolyzer 200 and Fuel Cell 200. These features include clear process diagrams, (almost) all industry-scale components and controls, hands-on learning opportunities, and safe processes.

All process data is digitally recorded. The software integrated into our educational devices can analyze this data, compare it with theoretical models and real-world performance, and thus help students understand efficiency and effectiveness in a practical, meaningful way.