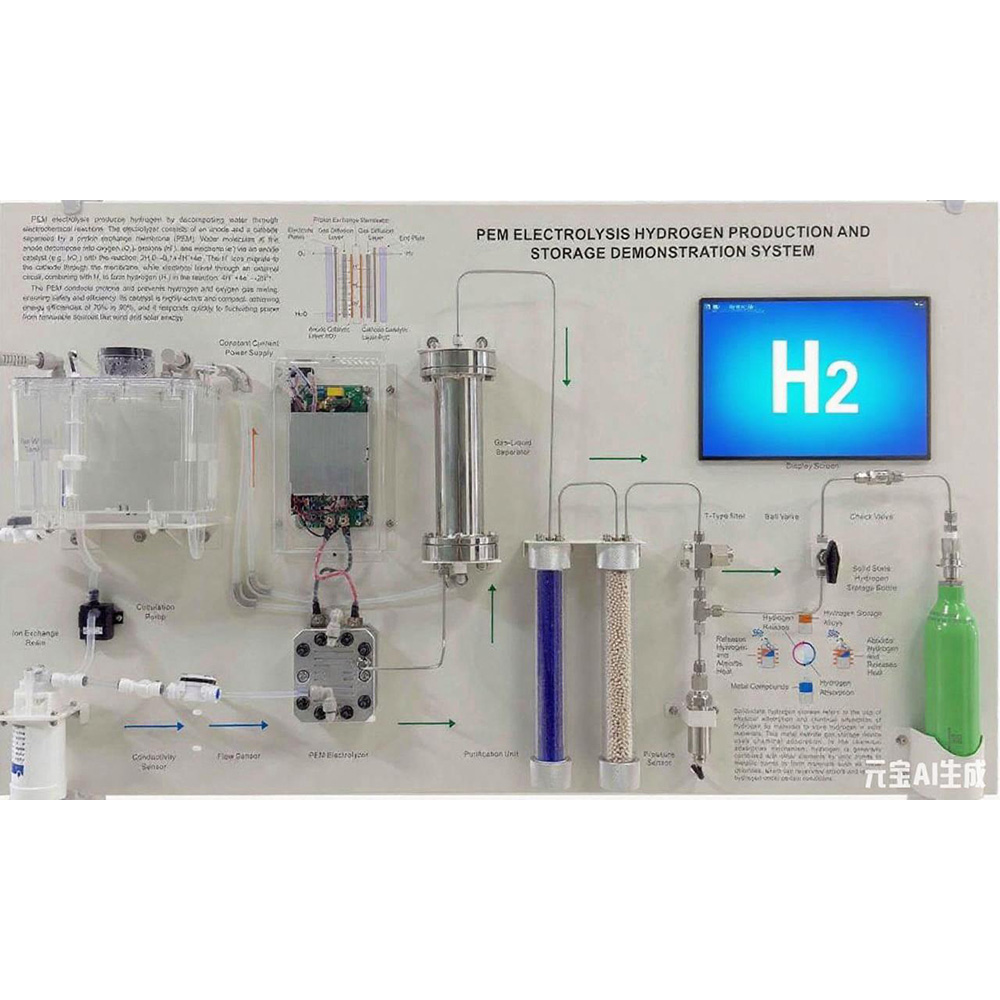

PEM Electrolyzer 200

| ELECTROLYZER DATA | |||||

| No. Cells | 10 | ||||

| PHYSICAL PROPERTIES | |||||

| Universal Gas Constant | R | [J/(mol K)] | 8.314 | ||

| Temperature | T | [K] | 298 | ||

| amb. Pressure | p | [hPa] | 1013 | ||

| Faraday Constant | F | [As/mol] | 96,485.33 | ||

| PROPERTIES HYDROGEN | |||||

| Valence | z | 2 | |||

| net calorific Value | Hu | [MJ/m³] | 10.79 | ||

| gross calorific Value | Hs | [MJ/m³] | 12.75 | ||

| Number | MEASUREMENT [EXAMPLE] | ||||

|---|---|---|---|---|---|

| VOLTAGE STACK | VOLTAGE CELL | CURRENT | HYDROGEN MASSFLOW TOTAL | HYDROGEN MASSFLOW CELL | |

| [V] | [V] | [A] | [cm³/s] | [cm³/s] | |

| 1 | 25 | 2.5 | 0 | 0 | 0 |

| 2 | 25 | 2.5 | 0.5 | 0.3 | 0.03 |

| 3 | 25 | 2.5 | 1 | 0.6 | 0.06 |

| 4 | 25 | 2.5 | 1.5 | 0.9 | 0.09 |

| 5 | 25 | 2.5 | 2 | 1.2 | 0.12 |

| 6 | 25 | 2.5 | 2.5 | 1.5 | 0.15 |

| 7 | 25 | 2.5 | 3 | 1.8 | 0.18 |

| 8 | 25 | 2.5 | 3.5 | 2.1 | 0.21 |

| 9 | 25 | 2.5 | 4 | 2.4 | 0.24 |

| 10 | 25 | 2.5 | 4.5 | 2.7 | 0.27 |

| 11 | 25 | 2.5 | 5 | 3 | 0.30 |

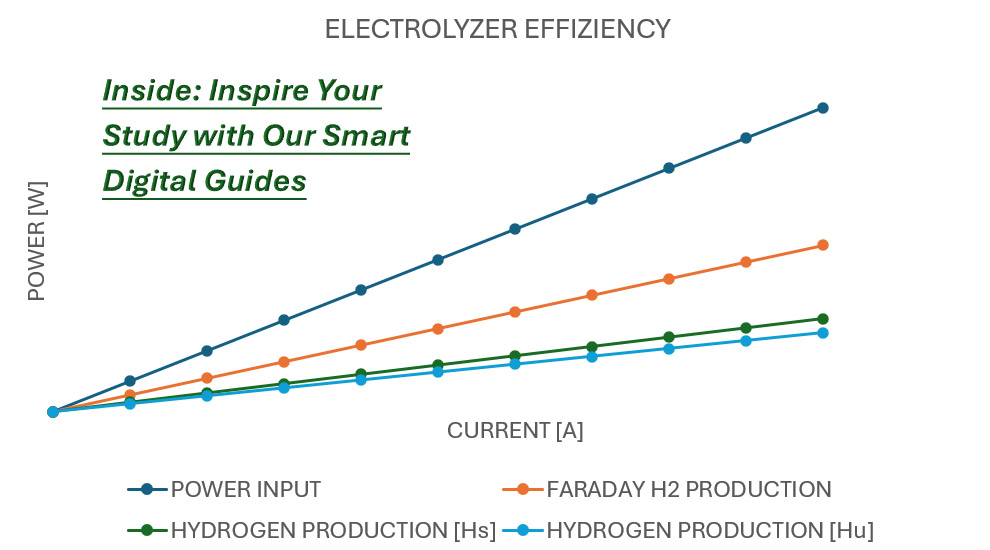

| Number | CALCULATION | ||||

|---|---|---|---|---|---|

| POWER INPUT | HYDROGEN MASSFLOW FARADAY | POWER FARADAY [Hu] | POWER HYDROGEN [Hs] | POWER HYDROGEN [Hu] | |

| [W] | [cm³/s] | [W] | [W] | [W] | |

| 1 | 0.0 | 0.00 | 0.0 | 0.0 | 0.0 |

| 2 | 1.3 | 0.06 | 0.7 | 0.4 | 0.3 |

| 3 | 2.5 | 0.13 | 1.4 | 0.8 | 0.6 |

| 4 | 3.8 | 0.19 | 2.1 | 1.1 | 1.0 |

| 5 | 5.0 | 0.25 | 2.7 | 1.5 | 1.3 |

| 6 | 6.3 | 0.32 | 3.4 | 1.9 | 1.6 |

| 7 | 7.5 | 0.38 | 4.1 | 2.3 | 1.9 |

| 8 | 8.8 | 0.44 | 4.8 | 2.7 | 2.6 |

| 9 | 10.0 | 0.51 | 5.5 | 3.1 | 2.6 |

| 10 | 11.3 | 0.57 | 6.2 | 3.4 | 2.9 |

| 11 | 12.5 | 0.63 | 6.8 | 3.8 | 3.2 |

Hydrogen Chart

* Hinweis: Das Diagramm enthält nur Beispieldaten. Die tatsächlichen Daten sind maßgebend.

Compliant with Directive 2006/42/EC

• Conforms to DIN EN ISO 12100 – Safety of Machinery: General design principles, risk assessment, and risk reduction

• Equipped with SIEMENS SMART industrial-grade PLC control system

• Integrated multi-level safety monitoring

• Hydrogen stored in solid-state, low-pressure (< 1.6 MPa) containers

• Comprehensive, standards-compliant, and modern didactic documentation

• IoT (Internet of Things) enabled

All processes presented in a practical, clear, illustrative, and calculable way – fully digitally traceable

The system is clearly structured and robustly built, enabling pupils and students to carry out hands-on experiments under clear didactic guidance. This approach allows them to gain an engaging and memorable understanding of hydrogen by directly combining theory with practice.

Up to 500ml/min Production efficiency.

Up to 250W Electricity consumption.

| Device | Specification | Unit | Value |

|---|---|---|---|

| PEM Electrolyzer | Hydrogen Output | ml/min | 500 |

| Oxygen Output | ml/min | 250 | |

| Power Supply Voltage | V | 9 | |

| Power Supply Current | A | 25 |

Water to H2 Production up to 500ml/min. Hands-on practice, digitally traceable.